When you have work that needs to be done in an elevated work area, scissor lifts are a popular job site tool.

But there are so many different models to choose from, and many of these models are similar — but, they are not the same. How do you know which one is right for your job site?

Choosing the right scissor lift greatly depends on what the machine will be doing — and where it will be doing it. In general, electric-drive scissor lifts can offer you longer runtimes and promote quieter, cleaner working environments, while hydraulic drive scissors are known for their simplicity, durability and lower initial purchase price.

This means that selecting a scissor lift with the right drive system — electric or hydraulic-powered — to match job site conditions and the work that needs to be done overhead is very important.

Know the power supply

As you know, JLG offers both electric and hydraulic drive scissor lifts: Our premium ES-series and our value R-series. Because they share a common chassis, these scissor lift models may look the same on the outside, especially from a distance (think about looking out from a rental store counter into a yard full of equipment and trying to pick out a hydraulic drive versus an electric drive model). If you aren’t as familiar with our machines, identifying their drive system might not be an intuitive task, and it might not be until you can get close enough to take a look inside that you will know for sure what kind of drive motor the machine is equipped with.

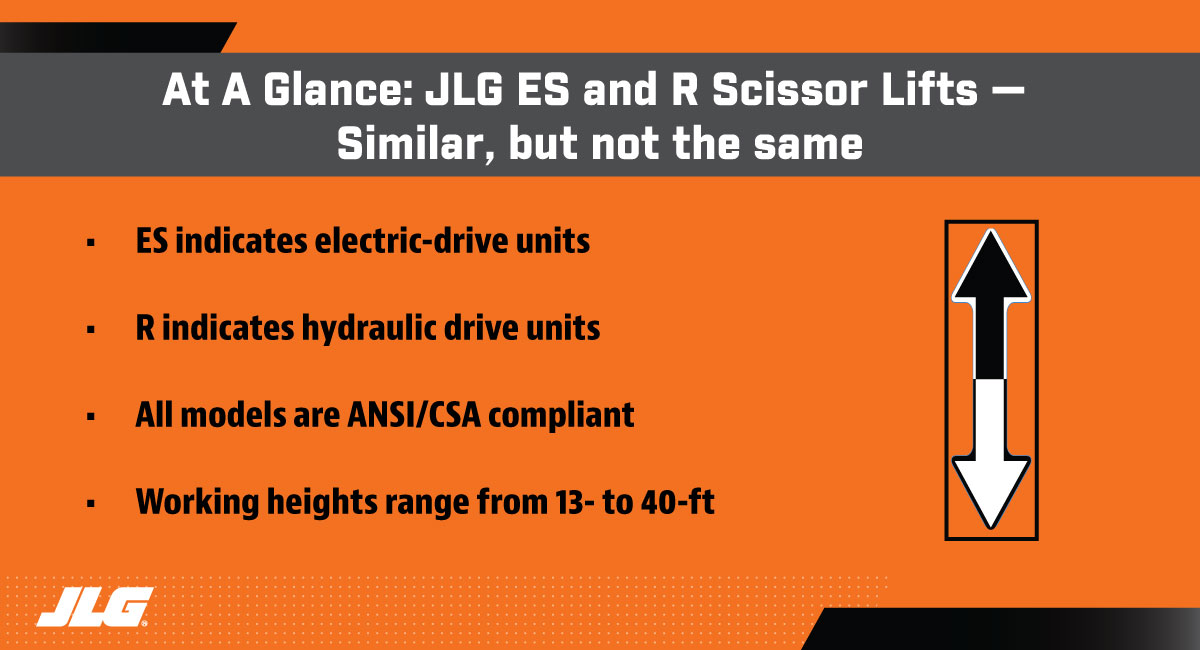

That’s why our new nomenclature and labeling system on these models can be your guide for evaluating our different models and selecting the one that’s right for your job site needs. For electric drive models, the ES before the model number (color coded in electric blue) indicates electric drive units. The R before the model number (color coded in black) indicates hydraulic drive units.

(This rationalization is similar for our rough-terrain models — RT lets you know the model is engine powered and ERT with electric blue color coding lets you know the model is electric powered.)

Know the applications

Both JLG scissor lift lines are engineered to deliver proven performance through smart, simple technology to maximize your uptime in ways other scissor lifts can’t, but because of their different drive systems, they each have their own unique place in the market.

JLG electric ES models are effectively designed for work in more sensitive conditions, like retail applications that require a full day’s work from the scissor lift without recharging or cold storage and freezer environments where the models’ electric drive and pump/cylinder design are less impacted by the change in viscosity of the oil. They are also perfect for use in buildings with more delicate flooring and carpet, like hotels and hospitals, due to their reduced leak points. Customers who evaluate the total cost of ownership throughout the life of the machine lean heavily towards purchasing ES models because these models can reduce a rental company’s service footprint (trucks, technicians, dispatchers, etc.).

JLG hydraulic drive R-series models are affordably designed for work in rugged conditions, like general construction and mechanical work applications. They offer the power and performance to be productive in general construction and mechanical work applications, as well as specialized trade work like drywalling, electrical, maintenance, painting and plumbing tasks.

Know the similarities

Despite the differences in drive systems, JLG offers a full range of models in both our ES and R-series. Our R-series has offerings ranging from 19- to 40-ft platform heights. Our ES-series has 13- to 32-ft platform heights. Both Series are ANSI A92.20/CSA B354 standards compliant.

And, our engineers at JLG have made sure that you don’t have to compromise on the attributes that matter to you most — including common operators control for transition between machines, common service points, innovative technology and reliable performance — when choosing one or the other. The ES and R-series also share common technologies, such as variable tilt technology to increase the working envelope on slopes. And, all models can also accommodate a variety of options and accessories, such as JLG® Mobile Control, QuikAccess Rails, QuikFold rails, smart charger, USB charger and phone holster.

No matter what your job site needs are, you have options with JLG scissor lifts, which gives you the opportunity to choose the one that makes the most sense for your business.

Want to learn more about the JLG ES and R-series scissor lifts?

Want to stay up to date with industry news and trends similar to this? Make sure you subscribe below to receive monthly updates from Direct Access with newly posted content so you never miss important information.