John Boehme

John Boehme

Senior Product Manager - Telehandlers

____

JLG Industries

Advancements that increase operator confidence and productivity and drive safety improvements on job sites influence JLG® and SkyTrak® product development. There are always “jobs to be done,” and at JLG, we believe that we have a responsibility to be more than an equipment manufacturing company — we are committed to understanding our customers’ job site challenges and partnering with them to develop solutions that deliver tangible benefits to their businesses.

We develop new features and functionality as a result of our teams watching how telehandlers work on job sites, as well as talking with operators that use this type of equipment every day. Receiving input ensures that when we launch the product, it’s the right solution for our customers. We innovate to bring solutions to market that solve these unmet needs.

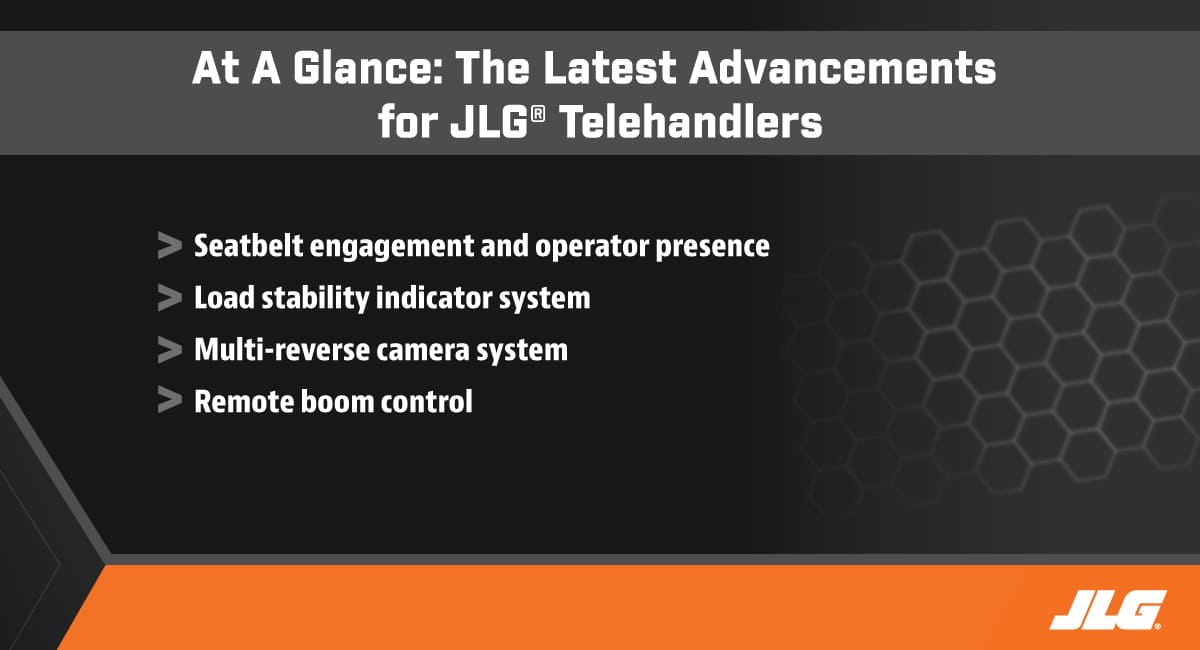

Here are highlights of our latest telehandler features based on our voice-of-the-customer work…

A Seatbelt Engagement and Operator Presence option for JLG® 742, 943, 1043, 1055 and 1255 telehandler models. This system, which includes seatbelt engagement assurance and operator presence functionality, as well as a high visibility orange seatbelt, uses visual and audible alarms, as well as limits machine functions, to enhance safety during telehandler operation.

Seatbelt engagement assurance functions by producing a visible and audible alarm that activates whenever an operator is seated and unbuckled. For example, when the operator is seated with the vehicle ignition key on, alarms will be activated immediately and continuously. The alarms will cease when the operator leaves the seat or turns the vehicle ignition off. The alarms are intended to alert and remind the operator and will not prevent engine start up or hydraulic and drive functions, similar to seat belt alarms in automobiles.

Operator presence functionality prohibits engine start and hydraulic functions if an operator is not present. Additionally, if the system detects a loss of seat pressure during operation, one of the following will occur:

- If the park brake is engaged and the transmission is in neutral, hydraulic controls are disabled. Upon returning to a seated position, the hydraulic controls are enabled.

- If the park brake is disengaged and the transmission is in neutral, hydraulic controls are disabled and the cabin alarm sounds continuously. Upon returning to a seated position, hydraulic controls are enabled, and the cabin alarm will cease.

- If the park brake is disengaged and the transmission is in forward or reverse, hydraulic controls are disabled, the cabin alarm sounds continuously, and the transmission shifts to neutral. Upon returning to a seated position, hydraulic controls are enabled, and the cabin alarm will cease. The transmission will need to be returned to neutral to allow the system to reset prior to re-engaging forward or reverse travel.

Load Stability Indication (LSI) system — this system aids operators by helping them to remain within the longitudinal or forward load capacity of the telehandler. It’s comprised of four primary components:

- The first is a sensor attached to the rear axle, which is able to measure the weight applied to the rear axle of the vehicle. The sensor on the rear axle provides the rear axle load measurement to the vehicle control system.

- The second part of the LSI system is the vehicle control system, which is the brain of the vehicle, collecting and transmitting data and commands to many parts of the vehicle. The vehicle control system sends data to the LSI display in the cabin of the vehicle.

- The third part of the LSI system is the LSI display that provides the operator a visual indication of the forward stability status of the vehicle. There are six levels of indication in the display, progressing from green (load within capability) to orange (load capability nearing limit) to red (load capability at the limit). If the forward load capability of the vehicle is reached, a red lamp is illuminated on the display. When this happens, an audible alarm is activated, and the vehicle control system will stop and prevent further activation of many of the vehicle hydraulic implement functions. The only implement functions available to the operator to correct the stability of the vehicle are retract boom (in) and lift boom (up). When stability of the vehicle has been improved, the audible alarm will turn off and the display will return to orange.

- The fourth and final part of the LSI system is the LSI Override Switch, which the operator may choose to use in order to continue operating the vehicle with the red lamp illuminated and hydraulic implement functions inhibited.

Backup camera technology — The JLG multi-reverse camera system can help operators see a broader area on the backside of the machine, giving operators more confidence when backing up. This feature increases job site awareness by displaying multiple views from behind the machine — left, right, and rear.

Boom control technology — JLG remote boom control enables operators to control the telehandler’s boom from outside the cab. This feature provides operators with improved visibility during load placement.

What do rental centers need to consider when bringing on new telehandlers with these latest advancements into their rental fleets?

When considering adding new model telehandlers into a rental fleet, it is important for rental centers to understand the particular wants and needs of the local customer base. Do they need/want models with higher reach or more compact models? Or does the current product range offered meet their needs? Are they looking for models with new technology to help improve job site efficiencies and are willing to pay a higher rental rate for machines with these features? Or are they looking for basic models that lift and place with limited technology? All of these things should be taken into consideration prior to investing.

Knowing what’s important to the local customer base should help guide rental fleet purchases. If a rental company doesn’t have a good handle on the preferences of their local customer base, they risk stocking new models with new technologies that their customers don’t want — or basic models that don’t have the features customers desire.

Once the purchase decisions are made and new models added to a fleet, there’s a learning curve to be dealt with. First, the rental company and its sales team must learn what the new model and any associated technology have to offer not only their business, but also how these same features benefit their customers businesses. Marketing these models and being able to effectively communicate the customer benefits will positively impact utilization rates. The better job one does communicating the advantages of the new models, the more likely customers will be to request them, thereby accelerating the user adoption rate.

Bringing on new models with new technology will also require training for service personnel. Ensuring the service team is equipment to support the units once they are in the field is crucial to maintain a high level of customer support.

To learn more about how advances in JLG telehandlers can bring more power, reach and versatility to the job site, click here.

Do you want to stay up to date with industry news and issues similar to this? Make sure you subscribe below to receive monthly updates from Direct Access with newly posted content so you never miss important information.