Nate Hoover

Nate Hoover

Director - Product Management, Boom Lifts

____

JLG Industries

Boom lifts, in general, are common job site tools, and we continue to see strong demand for all models, including articulated units. JLG® engine-powered and electric & hybrid articulating boom lifts give operators extra reach when they need to work over and around obstacles on the job site — the larger work envelope on this style of machine provides operators with access to those hard-to-reach places.

Below are some insights into what is going on with articulated boom lifts in today’s market conditions.

What is the largest trend in the articulated boom lift market right now?

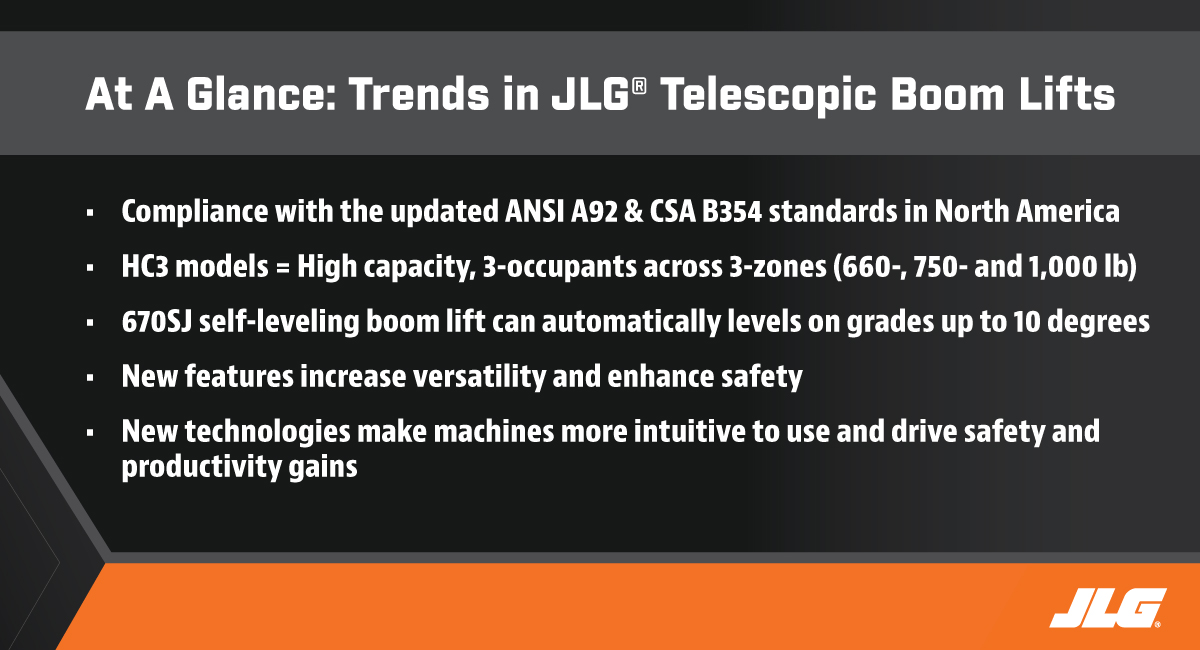

The biggest trend in the articulated boom lift market in recent years relates to compliance with the updated ANSI A92 and CSA B354 standards in North America, which has created an increased demand for higher capacity machines because of the required addition of load and tilt sensing systems.

In response, JLG expanded the allowable work envelope across its line of HC3 (High capacity, 3-occupants across 3-zones – 660-, 750- and 1,000 lb) boom lifts, which includes four articulated models including the: 450AJ, 600AJ, 660AJ and 800AJ. These JLG boom lifts allow customers the ability to bring more people and more materials to the work area for greater productivity. HC3 models are heavier weight than their standard boom counterparts for added durability; however, they retain the same footprint for ease of transport and ease of use.

What are some of the stand-out features of JLG’s HC3 boom lifts?

In addition to the higher capacity, the JLG HC3 boom lifts incorporate JLG’s advanced load sensing solution, which includes built-in sensor technology that is advanced enough to allow operators to respond to an overload situation more efficiently. By simply removing or unloading items from a JLG machine’s platform, for example, the MEWP will recognize when its back within its rated load capacity, enabling operations to resume without the need to recalibrate the machine. And, it is a zero-load calibration system, which means that customers don’t need any complex technical support or a 1,000-lb reference weight.

The JLG tilt sensor technology allows operators to utilize restricted functionality to return the machine to a work area within its allowable operating range. Once the machine recognizes that its back within its rated zone, operators are able to resume operations.

What mega trends affect the market for this product?

In addition to standards compliance, another trend that is impacting the articulated boom lift market is the increasing use of these machines in urban environments. Urbanization is resulting in less open space on and between job sites, which drives greater demand for high reach equipment with a compact footprint — and articulated boom lifts are no exception. Today, smaller models are gaining in popularity because of their ability to work in tight quarters.

Also, we continue to respond to the market demand for more electrified equipment options. JLG currently offers many boom lift models, including articulated, telescopic, straight mast and compact crawler, with electric or optional electric power. Specific articulating boom lift models include the JLG H340AJ and H800AJ, E300 Series, E400 Series and the E450AJ.

And, one of the biggest responsibilities we have today as the leading global aerial equipment manufacturer is the need to continually evolve and introduce technologies and features that will enable our customers to be more successful and increasingly efficient on the job, while also improving safety. For that reason, digital tools like BIM and augmented reality (AR) apps are becoming more prevalent for planning before and during construction. These tools improve job site efficiencies, making them valuable resources for contractors, as they help users identify the right boom for the job at hand. Whether on-the-go or in the office, digital tools like these from JLG can offer contractors real-time solutions to job site challenges.

What are the main uses/applications for articulated boom lifts?

The articulated boom lift market is quite mature, applications and uses for this type of equipment are well established — mostly in industrial construction, maintenance, and repair tasks, as well as in congested spaces, like urban areas and city centers, that require operators to get “up and over” objects to complete work at height.

The specific work-at-height requirements on a particular project continue to dictate when it is best to use an articulated boom lift. The best way to distinguish the applications and uses for articulated boom is that these types of lifts are better suited for moving people and materials around obstacles and into different positions with agility, such as when operators need to reach over or around objects like chimneys, ceiling joists or roof trusses, HVAC or electrical fixtures, the floors of a building under construction or warehouse shelves, and so on. Or, because job site conditions require a machine with a more compact footprint and narrow operating profile, especially zero tail swing models, for use in space-restricted areas. These machines are also helpful in situations where overhead work is located so that operators need access to multiple angles and reach in order to get it done.

To learn more about when to use an articulated boom lift, click here.

Do you want to stay up to date with industry news and issues similar to this? Make sure you subscribe below to receive monthly updates from Direct Access with newly posted content so you never miss important information.